Awọn ohun elo Bevel

Apoti okun Kireni

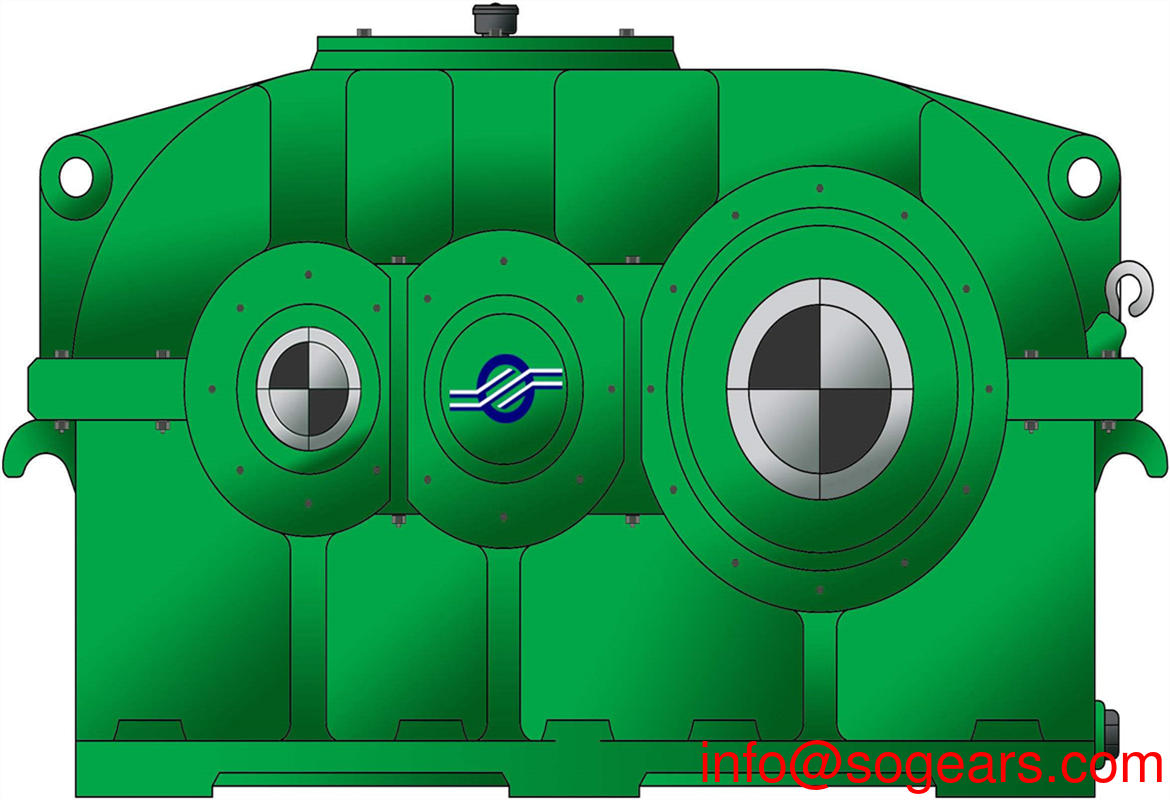

Z series hardened cylindrical spur crane gearbox, mainly including ZDY (single-stage), ZLY (two-stage), ZSY (three-stage) and ZFY (four-stage) four series, small size, compact structure, high overload capacity, power up to 132KW Left and right, the machine efficiency is up to 97%, the vibration is small, the noise is low, the energy saving is high, the high-quality forged steel material and the steel cast iron box body are selected, the gear surface is subjected to high-frequency heat treatment, and the gear pair is precision processed. Output speed: 0.04--810r/min, output torque: up to 18000 N.m, motor power: 0.12--132KW.

ZSY type Crane gearbox is a parallel shaft series and vertical axis Crane gearbox.

The Crane gearbox mainly includes the parallel shaft series and the vertical shaft series. The parallel shaft Crane gearbox is produced according to the national standard (GBl9004—88). The optimized design has the international advanced level in the 1980s. It mainly includes ZDY (single). Four series, ZLY (two-stage), ZSY (three-stage) and ZFY (four-stage), vertical shaft Crane gearbox is produced according to national standard (JB/T9002-1999), and the input shaft is perpendicular to the output shaft. Directional transmission, which mainly includes three series of DBY, DCY and DFY. ZSY type Crane gearbox includes: ZSY160, ZSY180, ZSY200, ZSY224, ZSY250, ZSY280, ZSY315, ZSY355, ZSY400, ZSY450, ZSY500, ZSY560, ZSY630, ZSY710.

Application range: (2) The peripheral speed of the gear drive is not more than 20 m / s. (3) Working environment—40~50°C. If it is lower than 0°C, the lubricating oil should be preheated to above 0°C before starting. Crane gearbox can be used in both forward and reverse directions. (4) It can be widely used in metallurgy, mining, chemical, building materials, lifting, transportation, textile, paper, equipment, plastics, rubber, engineering machinery, energy and other industrial sectors.

Application range: (1) Input speed is generally n, ≤1500r/min (2) The peripheral speed of the gear drive is not more than 20 m / s. (3) Working environment—40~50°C. If it is lower than 0°C, the lubricating oil should be preheated to above 0°C before starting. Crane gearbox can be used in both forward and reverse directions. (4) It can be widely used in metallurgy, mining, chemical, building materials, lifting, transportation, textile, paper, equipment, plastics, rubber, engineering machinery, energy and other industrial sectors.

The Crane gearbox mainly includes the parallel shaft series and the vertical shaft series. The parallel shaft Crane gearbox is produced according to the national standard (GBl9004—88). The product is optimized and has the international advanced level in the 1980s. It mainly includes ZDY (single). Four series, ZLY (two-stage), ZSY (three-stage) and ZFY (four-stage), vertical shaft Crane gearbox is produced according to national standard (JB/T9002-1999), and the input shaft is perpendicular to the output shaft. Directional transmission, which mainly includes three series of DBY, DCY and DFY.

Installation precautions are:

1. When lifting the whole box, the lifting hole of the lower box must be used, and the upper box lifting hole should not be used for lifting.

2. The gear box should be placed horizontally when transported and stored, and fixed on the support.

3. Do not drag and pull the gearbox to avoid damaging the bottom surface.

4. The gearbox installation base requires sufficient rigidity. There should be a backing plate under the cabinet. The level of the foundation mounting surface is required to be 0.04/1000.

5. After tightening the anchor bolts, check the bolts near the bolts. When the bolts are loose, the cabinet moves, indicating that the foundation is not flat or the gaskets are not well-padded and should be recalibrated.

6. After adjusting the horizontal plane, the input shaft requires a coaxiality tolerance of ¢0.040 for the motor shaft. The input shaft coupling must be installed in accordance with its standard requirements.

Features: (1) The main parameters such as center distance and nominal transmission ratio are optimized, and the main parts and parts are interchangeable. (2) The gears are made of high-quality alloy steel by carburizing and quenching, and the hardness of the tooth surface reaches HRC54-62. (3) Small size, light weight, high precision, large carrying capacity, high efficiency, long life, high reliability, stable transmission and low noise. (4) Generally use oil pool lubrication, natural cooling, when the thermal power can not be met, you can use circulating oil lubrication or fan, cooling coil cooling.

According to the standard JB/T8905.3-1999, the QJG-L type Crane gearbox is mainly used for the crane running mechanism and parts of the crane, the crane, the loading and unloading bridge, etc., and can also be used for other equipments that need vertical installation. .

Features: 1. QJG-L type Crane gearbox adopts cast iron box body and base type side mounted vertical Crane gearbox 2, three-stage transmission, the speed ratio is 16-100 3, the series has 7 specifications, the nominal center distance is 140-400mm 4. The small size Crane gearbox is oil bath type lubrication, and the 280 or more speed Crane gearbox is concentrated by oil injection lubrication. Other features are the same as QJ type Crane gearbox

Type: Structure: QJG-L type Crane gearbox is a three-stage vertical type with base Crane gearbox Assembly type: QJG-L type Crane gearbox has 6 assembly forms Model: QJG-L140/QJG-L170/QJG-L200/QJG-L236/QJG-L280/QJG-L335/QJG-L400

The QJG-T type Crane gearbox is based on the QJG-L type Crane gearbox. It is mainly used for the crane's running mechanism. It can also be used in other machines that require a vertical set to replace the ZSC (A) type Crane gearbox. . The output end of the QJG-T type Crane gearbox is a conical sleeve. Crane gearbox is sleeved on the passive shaft of the main machine, and its end is fixed, and the weight of Crane gearbox is also supported on the shaft. A hole is arranged in the upper part of the box body, and is fixed on the bracket by a pin shaft.

The box body is divided into three parts, the lower tank body oil is not easy to leak, and the size of the output shaft center line to the lower end limit position is relatively small. Other features are the same as QJG-L type Crane gearbox

Crane gearbox is generally used for transmission equipment with low speed and high torque. The ordinary Crane gearbox of the motor will also have several pairs of identical gears to achieve the desired deceleration effect. The ratio of the number of teeth of the large and small gears is the transmission ratio. With the continuous development of Crane gearbox industry, more and more enterprises have applied Crane gearbox.

Crane gearbox 1. R series coaxial helical Crane gearbox is manufactured in accordance with international technical requirements and has high scientific and technological content. 2, save space, reliable and durable, with high overload capacity, power up to 132KW; 3, low energy consumption, superior performance, the efficiency of Crane gearbox is as high as 95% or more; 4. Low vibration, low noise and high energy saving; 5, the selection of high-quality forged steel materials, steel cast iron box, the surface of the gear after high-frequency heat treatment; 6. After precision machining to ensure the parallelism of the shaft and the requirements of the positioning bearing, Crane gearbox that forms the helical gear transmission assembly is equipped with various types of motors, which are combined into mechatronics, which fully guarantees the quality characteristics of the products.

Crane gearbox: 1. The high speed shaft rotation is not more than 1500 rpm. 2. The peripheral speed of the gear drive is not more than 20 m / s. 3. The working environment temperature is -40-45 °C. If it is lower than 0 °C, the lubricating oil should be preheated to above 0 °C before starting. 4. The Crane gearbox can be used in both forward and reverse directions.

1. The gear is made of high-strength low-carbon alloy steel by carburizing and quenching. The hardness of the tooth surface is up to HRC58-62. The gears are all CNC grinding technology with high precision and good contact. 2. High transmission rate: single stage is greater than 96.5%, double level is greater than 93%, and third level is greater than 90%. 3. Smooth operation and low noise. 4. Small size, light weight, long service life and high carrying capacity. 5. Easy to disassemble and easy to install

The Crane gearbox uses the gear transmission of all stages to achieve the purpose of speed reduction. Crane gearbox is composed of gear pairs of various stages. For example, the gear can be driven by a small gear to achieve a certain deceleration, and then a multi-stage structure is adopted. , you can greatly reduce the speed.

iṣẹ:

1. The gear is made of high-quality alloy steel for carburizing and quenching. The hardness of the tooth surface is up to 60±2hrc, and the precision of the tooth surface grinding is up to 5-6.

2, using computer reshaping technology, pre-reform the gear, greatly improving the load capacity of Crane gearbox.

3, from the box to the internal gear, using a completely modular structure design, suitable for large-scale production and flexible selection.

4. The standard Crane gearbox model is divided according to the torque decrement form, which avoids power waste compared with the traditional equal division.

5, using cad / cam design and manufacture to ensure the stability of quality.

6, using a variety of sealing structures to prevent oil leakage.

7, multi-directional noise reduction measures to ensure the excellent low noise performance of Crane gearbox.

In the long-term operation of Crane gearbox, there are often faults such as wear and leakage. The most important ones are: 1. The bearing chamber of Crane gearbox is worn, which in turn includes the wear of the bearing housing of the housing, the bearing chamber of the housing, and the bearing chamber of the transmission. 2. The shaft diameter of the gear shaft of Crane gearbox is worn, and the main wear parts are in the shaft head and keyway. 3. The bearing position of Crane gearbox drive shaft is worn. 4. Crane gearbox joint surface leaks.

A Crane gearbox is a type of transmission that increases the wear of its internal transmission as it works longer.

For the leakage problem, the traditional method needs to disassemble and open Crane gearbox, replace the sealing gasket or apply the sealant, which is not only time-consuming and laborious, but also difficult to ensure the sealing effect, and leakage will occur again during operation. The polymer material can be used to treat leakage on site. The material has excellent adhesion, oil resistance and 350% elongation, which overcomes the impact caused by the vibration of Crane gearbox, and solves the problem of leakage of Crane gearbox for the enterprise.

The loss includes the following three aspects:

1. Isonu ija didanubi laarin eyin.

2. Pipadanu ni awọn biarin, awọn gbigbe pẹtẹlẹ ati awọn gbigbe awọn sẹsẹ.

3. Asesejade ati agug ti ipadanu ipadanu.

Crane gearbox, Crane gearbox, hardened Crane gearbox mainly includes parallel shaft series and vertical shaft series. Parallel shaft Crane gearbox is produced according to standard (GBl9004— 88)). The product has been optimized and has eight In the advanced level of the decade, it mainly includes four series of ZDY (single-stage), ZLY (two-stage), ZSY (three-stage) and ZFY (four-stage). The vertical shaft Crane gearbox is produced according to the standard (JB/T9002— 1999). The transmission device is arranged in the vertical direction of the input shaft and the output shaft, and mainly includes three series of DBY, DCY and DFY.

ZSY Crane gearbox, ZSY hard surface Crane gearbox, ZSY Crane gearbox application range (1) Input speed is generally n, ≤1500r/min ZSY Crane gearbox, ZSY hard surface Crane gearbox, ZSY Crane gearbox (2) The peripheral speed of the gear drive is not more than 20 m / s. (3) Working environment — 40~50°C, if it is lower than 0°C, the lubricating oil should be preheated to above 0°C before starting. Crane gearbox can be used for both positive and negative directions. (4) It can be widely used in metallurgy, mining, chemical, building materials, lifting, transportation, textile, paper, equipment, plastics, rubber, engineering machinery, energy and other industrial sectors.

ZSY Crane gearbox, ZSY hard surface Crane gearbox, ZSY Crane gearbox features (1) The main parameters such as center distance and nominal transmission ratio are optimized, and the main parts and parts are interchangeable. (2) Generally use oil pool lubrication, natural cooling, when the thermal power can not be met, you can use circulating oil lubrication or fan, cooling coil cooling. (3) The gears are made of alloyed steel by carburizing and quenching, and the hardness of the tooth surface reaches HRC54— 62. (4) Small size, light weight, high precision, large carrying capacity, high efficiency, long life, high reliability, stable transmission and low noise.

Example of representation: 1.ZSY three-stage cylindrical Crane gearbox 2. Specifications are: 160, 180, 200, 224, 250, 280, 315, 355, 400, 450, 500, 560, 630, 710. 3. Example of representation method: 4. Steering regulations: The speed Crane gearbox with backstop can only be operated in one direction. The steering regulation is: facing the output shaft, the output shaft runs clockwise as “S”, counterclockwise operation is “N””.

Crane gearbox plays a role in matching the speed and transmitting torque between the prime mover and the working machine or the actuator. Crane gearbox is a relatively precise machine. The purpose of using Crane gearbox is to reduce the speed and increase the torque. According to the different gear stages, it can be divided into single-stage and multi-stage Crane gearboxs; according to the shape of the gear wheel, it can be divided into cylindrical Crane gearbox, bevel Crane gearbox and cone-cylindrical guide Crane gearbox; Divided into expansion, split and the same axis Crane gearbox. Crane gearbox is a separate component consisting of a gear drive, a worm drive, and a gear-worm drive enclosed in a rigid housing. It is often used as a reduction gear between the prime mover and the work machine. The function of matching the rotational speed and transmitting torque between the prime mover and the working machine or the actuator is widely used in modern machinery.

Selection method: 1. Known parameters and conditions Prime mover name, power P1 = kW speed n1 = r / min Work machine name. Power P2 = kW speed n2 = r / min Required gear ratio i=n1/n2 Hours of work per day h, number of starts per hour, hours per hour, Load characteristics (smooth, shock, severe impact), reliability requirements (general, higher, higher) 2, select the specification model according to the rated power

The nominal input power PA (Table 9-20) of the equal shaft series gearbox is stable according to the load. The working time per day is less than or equal to 10h, and the starting time is no more than 5 times per hour. The allowable starting torque is twice the working torque. For operation, the safety factor of the contact strength of a single pair of gears is about 1, and the probability of failure rate is less than or equal to 1%. When the gear box is running in both directions, the PN should be multiplied by a factor of 0.8-1.0 depending on the situation. When the reverse load is large, the commutation is frequent, and the selected reliability coefficient KR is low, the coefficient takes a smaller value, and vice versa. .

The rated power of the selected gearbox must meet: Pc=P2KAKsKR≤PA

Ninu agbekalẹ:

Pc=calculated power

P2 = working machine power

KA—use factor

Handling, setting, arranging pipes, machine operation, operation, maintenance and inspection must be carried out by personnel with specialized knowledge and skills. Failure to do so may result in injury or damage to the machine. 1. Do not disassemble and disassemble the gear unit while the equipment is running. In addition, even if the operation is stopped, the input and output flanges of Crane gearbox are connected to the motor and the other machine, and the parts other than the oil detection port, the oil supply port, and the inspection cover are not disassembled. There may be a drop in the gear of the gear, a rapid flight away, and other personal accidents or damage to the device. 2. Do not use in a range other than the gear unit specifications. May cause personal injury and damage to the device, etc. 3. Do not put your fingers and objects in the opening of Crane gearbox. Can cause injury and damage to the device, etc. 4. Do not use a damaged gear unit. Can cause injury and damage to the device.

The Crane gearbox uses the gear transmission of all levels to achieve the purpose of speed reduction. Crane gearbox is composed of gear pairs of various stages. For example, the gear can be driven by a small gear to achieve a certain deceleration, and then a multi-stage structure is adopted. , you can greatly reduce the speed. R, K, S, F four series of Crane gearbox are designed and manufactured on the basis of modular combination system. There are many motor combinations, installation forms and structural schemes. The transmission ratio is finely graded to meet different working conditions and realize electromechanical integration. Chemical.

The gear part is generally: 20CrMnTi, heat-treated grinding teeth, and the gear shaft is generally selected by 40Cr heat treatment grinding.

The high speed shaft rotation is no more than 1500 rpm. The gear drive has a peripheral speed of no more than 20 m/s. The working environment temperature is -40-45 °C. If it is lower than 0 °C, the lubricating oil should be preheated to above 0 °C before starting. The Crane gearbox can be used in both forward and reverse directions.

Iṣẹ ti o dara julọ lati ọdọ iwakọ gbigbe wa si apo iwọle rẹ taara.

wa Service

Gba ni Fọwọkan

Yantai Bonway Manufacturer Co.ltd

ANo.160 Changjiang opopona, Yantai, Shandong, China(264006)

T + 86 535 6330966

W + 86 185 63806647