YB2 jara ga-foliteji bugbamu-ẹri mẹta-alakoso asynchronous motor

|

M/S: |

|

RFQ: |

20629 |

|

ATTN: |

ALABOJUTO NKAN TITA |

DATE: |

15/08/2023 |

|

Adirẹsi: |

|

REPLY: |

amojuto |

|

Tẹli. Rara: |

|

||

|

FAX: |

|

||

|

Your Ref No: |

|||

|

SR |

QTY |

UNIT |

Apejuwe |

OYE EYO KAN |

LAPAPO IYE |

|

1 |

4 |

EA |

CONTACTOR; VOLTAGE RATING: 230-240 V, ELECTRICAL POLE QUANTITY: 3P, APPLICATION: MCC, LV SWITCHGEAR, VVVF; FFT: FREQUENCY: 50 HZ, MDB, CIRCUIT BREAKER 250A, TERMINAL KIT TYPE: ATK185, SHORT CIRCUIT CURRENT 85KA, VOLTAGE MAXIMUM 480V, CIRCUIT BREAKER 250A, SHORT CIRCUIT CURRENT 35KA, VOLTAGE MAXIMUM 600V, FUSE 400J SHORT CIRCUIT 75KA, VOLTAGE MAXIMUM 600V, FUSE 400/K5, SHORT CIRCUIT CURRENT 10KA, VOLTAGE MAXIMUM 600V, OLD PART NO: 1SFL491001R8822; MANUFACTURER PART NO: 1SFL487002R1322, EQUIPMENT MANUFACTURER: ABB, EQUIPMENT MANUFACTURER: MNS SYSTEM, EQUIPMENT TAG NO: EQ-0-EL-2A-03 |

|

|

Kindly provide the following information along with your offer:

|

1 |

Conformity Certificate from manufacturer (without which items not acceptable) and Related Certificates Details |

|

2 |

Air / Sea Freight Charges |

|

3 |

Ilu isenbale |

|

4 |

Delivery Period |

|

5 |

Validity Of Offer |

|

6 |

olupese |

|

7 |

Weight and Dimension of Shipment |

|

8 |

MTC Certificate |

WE APPRECIATE YOUR QUICK REPLY

Gbigba

Specification To delivery

YB2 jara ga-foliteji bugbamu-ẹri mẹta-alakoso asynchronous motor

|

No. Pos |

Name _ equipment |

Unit |

Q-ty |

HS CODE |

|

1 |

High-voltage asynchronous electric motor or analogue exceeding in technical characteristics and quality. itutu ọna Mains frequency - 50 Hz. Efficiency - 94%. Power factor - 0.84. Shaft axis height 630 mm, overall dimensions 1667x1400 mm. Ìyí ti aabo IP01 |

awọn kọnputa. |

2 |

|

|

2 |

Asynchronous electric motor High-voltage or analogue exceeding in technical characteristics and quality. Power - 500 kW; Rotation frequency - 750 rpm; Number of poles - 8; Climatic version - UHL4; Insulation class F . Cooling method IСO 1 (natural). Voltage - 6000V. Mains frequency - 50 Hz. Efficiency -94%. Power factor - 0.84. Shaft axis height 560 mm, Overall dimensions 1515x1225 mm. Degree of protection IPO 1 |

awọn kọnputa. |

2 |

|

|

|

Asynchronous electric motor Low voltage for cooling tower fans or equivalent specifications and quality. Power - 75 kW; Rotational speed - 176.5 rpm; Mains voltage 400V; Efficiency - 87.5%; Air-blown with degree of protection IP 55; Climatic version and placement category - U1.5 Overall dimensions 1222 x 1170 mm. Degree of protection IPO 1 |

awọn kọnputa. |

2 |

|

Note: The participant in the procurement procedures has the right to offer the supply of different brands and models (manufacturers) of similar equipment (spare parts) with technical characteristics, options improved and exceeding the stated requirements in this Terms of Reference, subject to the mandatory compatibility (identity) of the dimensions of the proposed equipment (spare parts) to the existing machinery, machinery and equipment (facility and infrastructure) of the Customer, with the presentation of the original international quality certificate.

|

1. CUSTOMER / CUSTOMER |

||

|

|

||

|

1.1 |

Organization |

OOO "SovTechFiltr" |

|

Organization _ |

Sovtechfilter LLC |

|

|

|

||

|

1.2 |

Ẹniti a o kan si |

Artem Igorevich Shilov |

|

The contact person |

Shilov Artem Igorevich |

|

|

|

||

|

1.3 |

El. mail |

|

|

imeeli |

||

|

|

||

|

1.4 |

Nọmba ise agbese |

07060706 |

|

Nọmba ise agbese |

||

|

YB2 jara ga-foliteji bugbamu-ẹri mẹta-alakoso asynchronous motor |

||

|

2. GENERAL DATA / COMMON DATA |

||

|

|

||

|

2.1 |

iru |

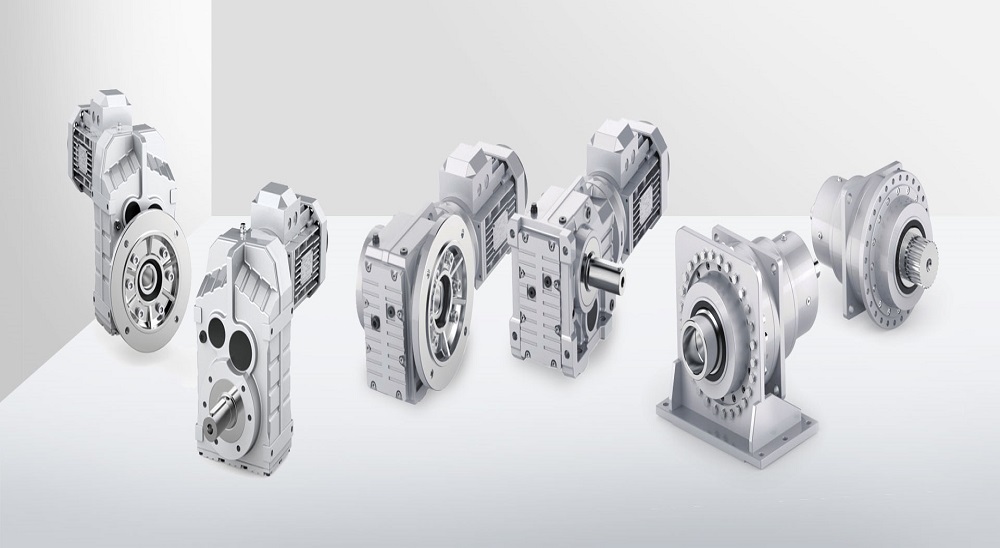

Motor-reducer |

|

iru |

|

|

|

|

||

|

2.2 |

Ìyí ti Idaabobo |

IP54 swear higher |

|

Ingress Idaabobo koodu |

||

|

|

||

|

2.3 |

Lapapọ opoiye |

4 PC. |

|

opoiye |

4 pc |

|

|

|

||

|

2.4 |

Igba ti iṣẹ |

Ko kere ju ọdun 5 |

|

Akoko iye |

Horse at least 5 years old |

|

|

|

||

|

3. TECHNICAL CHARACTERISTICS / SPECIFICATIONS |

||

|

|

||

|

3.1 |

Ṣiṣe awọn ipo-ṣiṣe |

50 Hz |

|

Iṣẹ igbohunsafẹfẹ |

50 Hz |

|

|

|

||

|

3.2 |

Sise foliteji |

380 |

|

Folti ẹrọ |

|

|

|

Power (necessary to pick up) kwt |

||

|

Revolutions 280 rev/min |

||

|

The torque on the output shaft is 60 Nm |

||

|

3.3

|

ibaramu otutu |

From – 40 ⁰ С to + 40 ⁰ С |

|

ibaramu otutu |

||

|

|

||

|

3.4 |

ọriniinitutu |

100% |

|

ọriniinitutu |

100% |

|

|

|

||

|

3.5 |

Insulation class according to МЕК 60085-2011 |

Class F and higher |

|

Insulation class according to IEC 60085-2011 |

Class F oath above |

|

|

3.6 |

Ipo iṣẹ |

S 1 according to IEC 60034-1-2014 |

|

Ipo isise |

S1 according to IEC 60034-1-2014 |

|

|

4. BODY / FRAME |

||

|

4.2 |

Ilẹ ilẹ |

Grounding on the body in the form of a pin |

|

Ilẹ ilẹ |

Grounding on the housing in the form of a stud |

|

|

|

||

|

4.3 |

The position of the distribution box |

Manufacturing material: cast iron or low-carbon steel |

|

Junction box position |

Material of manufacture: cast iron or low carbon steel with anti-corrosion coating It is forbidden to use a plastic or aluminum junction box |

|

|

1. ЗАКАЗЧИК / CUSTOMER |

||

|

|

||

|

1.1 |

agbari |

ООО «СовТехФильтр» |

|

Organization |

Sovtechfilter LLC |

|

|

|

||

|

1.2 |

Контактное лицо |

Шилов Артем Игоревич |

|

The contact person |

Shilov Artem Igorevich |

|

|

|

||

|

1.3 |

Imeeli meeli |

|

|

imeeli |

||

|

|

||

|

1.4 |

Номер проекта |

07060706 |

|

Nọmba ise agbese |

||

|

|

||

|

2. ОБЩИЕ ДАННЫЕ / COMMON DATA |

||

|

|

||

|

2.1 |

Iru |

Мотор-редуктор |

|

iru |

|

|

|

|

||

|

2.2 |

Ìyí ti Idaabobo |

IP54 and higher |

|

Ingress Idaabobo koodu |

||

|

|

||

|

2.3 |

Lapapọ |

4 PC. |

|

opoiye |

4 pc |

|

|

|

||

|

2.4 |

Aye iṣẹ |

O kere ju ọdun 5 |

|

Akoko iye |

O kere ju 5 ọdun |

|

|

|

||

|

3. ТЕХНИЧЕСКИЕ ХАРАКТЕРИСТИКИ / SPECIFICATIONS |

||

|

|

||

|

3.1 |

Igbohunsafẹfẹ ṣiṣẹ |

50 Hz |

|

Iṣẹ igbohunsafẹfẹ |

50 Hz |

|

|

|

||

|

3.2 |

Ṣiṣẹ foliteji |

380 |

|

Folti ẹrọ |

|

|

|

Мощность (необходимо подобрать) квт |

||

|

Обороты 280 об/мин |

||

|

Момент на выходном валу 60 Нм |

||

|

3.3

|

Ibaramu otutu |

От – 40 ⁰С до + 40 ⁰С |

|

ibaramu otutu |

||

|

|

||

|

3.4 |

Влажность |

100% |

|

ọriniinitutu |

100% |

|

|

|

||

|

3.5 |

Класс изоляции по МЭК 60085-2011 |

Класс F и выше |

|

Insulation class according to IEC 60085-2011 |

Class F and above |

|

|

3.6 |

Ipo isẹ |

S1 по IEC 60034-1-2014 |

|

Ipo isise |

S1 according to IEC 60034-1-2014 |

|

|

4. КОРПУС / FRAME |

||

|

4.2 |

Earthing |

Заземление на корпусе в виде шпильки |

|

Ilẹ ilẹ |

Grounding on the housing in the form of a stud |

|

|

|

||

|

4.3 |

Положение распределительной коробки |

Материал изготовления: чугун или низкоуглеродистая сталь |

|

Junction box position |

Material of manufacture: cast iron or low carbon steel with anti-corrosion coating It is forbidden to use a plastic or aluminum junction box |

|

YB2 jara ga-foliteji bugbamu-ẹri mẹta-alakoso asynchronous motor

(H355~560)

Awọn ayẹwo ọja

Code: 0AP.138-0109a

G Explosion Protection Group Co., Ltd

Kẹsán 20, 2009

katalogi

1. Overview 3

2. Model Description 4

3. Structural Description 4

4. Service conditions

5. Data imọ-ẹrọ

6. Structure, Installation, and Boundary Dimensions

7. Quality Assurance 6

8. Ordering Guidelines

Dear customer, first of all, thank you for your concern and support for our company's motor products. Before you purchase and choose motors, please carefully read this "Product Sample". It will tell you the basic knowledge of motor products and how to select the motor you need, so as to accurately purchase and better serve you.

1. Akopọ

The YB2 series high-voltage explosion-proof three-phase asynchronous motor is the latest product developed by our company on the basis of digesting and absorbing the manufacturing technology of high-voltage motors from Siemens in Germany, combined with our company's long-term stable production experience in the design and manufacturing of high-voltage explosion-proof three-phase asynchronous motors. It is a basic series of explosion-proof motors that is updated and replaced by our YB series. This series of motors adopts new technologies, materials, and processes, with exquisite material selection and excellent manufacturing. They have the characteristics of small size, light weight, beautiful appearance, high power, high efficiency, low noise, small vibration, safe and reliable operation, and convenient use and maintenance.

The shell protection and junction box protection level of this series of motors can be selected as IP54 or IP55, with cooling method IC411 and installation method IMB3. Different protection types, cooling methods, and installation methods can also be made according to user requirements.

This series of motors complies with the provisions of GB755-2000 "Rotating Electrical Machines - Rating and Performance", GB3836.1-2000 "Electrical Equipment for Explosive Gas Atmospheres - Part 1: General Requirements", and GB3836.2-2000 "Electrical Equipment for Explosive Gas Atmospheres - Part 2: Flameproof Type" d ". They are made into explosion-proof motors with explosion-proof markings ExdI, Exd II AT4, Exd II BT4, and Exd II CT4, suitable for Zone 1 with explosive gas atmospheres Zone 2 hazardous locations. As a prime mover, it can be widely used in mining, machinery industry, petrochemical industry, power plants and other industrial and mining enterprises to drive various general machinery, such as compressors, water pumps, crushers, cutting machines, transportation machinery, and other mechanical equipment.

ExdI is suitable for explosive gas environments in non mining working faces of coal mines with methane or coal dust.

Exd Ⅱ AT4 is suitable for explosive gas environments in Class II, Class A, temperature groups T1, T2, T3, and T4 used in factories.

Exd Ⅱ BT4 is suitable for explosive gas environments in Class II, Class B, temperature groups T1, T2, T3, and T4 used in factories.

Exd Ⅱ CT4 is suitable for explosive gas environments in Class II, Class C, temperature groups T1, T2, T3, and T4 used in factories.

The electric motor can be made into YB2-W outdoor type, YB2-TH indoor wet tropical type, YB2-THW outdoor wet tropical type, YB2-TA indoor dry tropical type, YB2-TAW outdoor dry tropical type, YB2-T indoor tropical type, YB2-TW outdoor tropical type, and YB2-WF1 outdoor medium corrosion resistant electric motor for climatic and environmental conditions. The installation size is the same as the basic series motor.

2. Apejuwe awoṣe

2.1 Meaning of motor model:

Y B 2-450 2-2W

Asynchronous motor

Flameproof environment code (outdoor)

Improved design number and number of poles (2 poles)

Axis center height (450mm) iron core length code (No. 2 iron core)

2.2 The significance represented by the explosion-proof mark of the motor:

Ex d Ⅱ B T4

Mark (explosion-proof) temperature group (T4)

Electrical equipment explosion-proof type (explosion-proof type) Electrical equipment category level (Class II, Class B)

YB2 jara ga-foliteji bugbamu-ẹri mẹta-alakoso asynchronous motor

3. Structural Description

This series of motors adopts an internationally popular compact structure, with heat dissipation ribs distributed on the inner and outer surfaces of the base and end cover. They are compact in size and have a beautiful appearance.

The stator adopts an external pressure structure with an insulation grade of F, and the stator coil is wound with insulated copper flat wire to form a coil. After being wrapped with main insulation and VPI overall coating, it has high electrical strength, mechanical strength, insulation performance, moisture resistance, and thermal stability.

The rotor adopts a squirrel cage structure, and after high-precision verification of dynamic balance, the motor runs smoothly with low vibration.

Selection of bearing structures based on different power and speed: H355~560-4, 6, and 8P adopt rolling bearings; H500-560-2P adopts sliding bearings (according to GB3836.2-2000 "Electrical Equipment for Explosive Gas Atmospheres - Part 2: Flameproof Type" d ", sliding bearing motors cannot be made of Exd Ⅱ CT4 structure). The bearings at both ends of the rolling bearing motor are equipped with non-stop oil injection and drainage devices, which can regularly replenish lubricating grease; The sliding bearing is an end cap spherical sliding bearing, which adopts

Using pressure oil supply lubrication, oil ring self-lubrication, or composite lubrication methods (freely selected by the user, or pressure oil supply lubrication if there are no special requirements from the user), and taking measures to prevent shaft current generation.

According to user needs, the motor can be equipped with bearing temperature measuring elements or instruments to monitor bearing temperature; Stator temperature measuring elements, instruments, and anti condensation heating devices can also be set according to user needs.

The explosion-proof structure of the motor adopts cylindrical, planar, and stop type explosion-proof types.

4. Service conditions

4.1. Environmental conditions for the use of electric motors:

4.1.1. The altitude shall not exceed 1000m.

4.1.2. The ambient air temperature varies seasonally and generally does not exceed 40 ℃.

Note: If the motor is specified to be used at altitudes exceeding 1000m or ambient air temperatures above 40 ℃, the provisions of GB755 should be followed.

4.1.3. The minimum ambient air temperature is -15 ℃ for motors with rolling bearings and 0 ℃ for motors with sliding bearings.

4.1.4. The maximum relative humidity of the ambient air shall not exceed 95% (when the temperature is 25 ℃) (underground in coal mines) or the average maximum relative humidity in the wettest month shall be 90%, and the average minimum temperature in that month shall not be higher than 25 ℃ (in factories).

4.1.5. Underground coal mines (non mining working faces) and factories with methane mixtures and coal dust explosion hazards have explosive mixtures formed by combustible gases or vapors and air with ignition temperature groups T1 to T4, respectively.

4.1.6. In a place without significant vibration.

4.1.7. In an environment without damaging metal insulation with gases and vapors.

4.1.8. Places with dripping water.

4.1.9. The installation category is Class III.

4.1.10. The pollution level is Level 3.

4.1.11. Applicable environmental conditions for derivative products (- W, TH, THW, TA, TAW, T, TW, WF1):

YB2 is a basic type suitable for indoor environments

YB2-W is suitable for outdoor environments

YB2-TH is suitable for indoor humid tropical environments

YB2-THW is suitable for outdoor humid tropical environments

YB2-TA is suitable for indoor dry tropical environments

YB2-TAW is suitable for outdoor dry tropical environments

YB2-T is suitable for indoor tropical environments

YB2-TW is suitable for outdoor tropical environments

YB2-WF1 is suitable for outdoor moderately corrosive environments

4.2. Electrical conditions for the use of electric motors:

4.2.1. Rated frequency: 50Hz.

4.2.2. The rated voltage is 3kV level (including 3kV, 3.3kV, 3.6kV), 6kV level (including 6kV, 6.3kV, 6.6kV), and 10kV level (including 10kV, 10.5kV, 11kV).

4.2.3. Working mode of the motor: S1 (continuous working system).

4.2.4. The rated power, rated voltage, rated frequency, and rating of the motor can be found in the data on the motor nameplate.

5. Imọ data

The electrical performance of YB2 series 6kV and 10kV motors should comply with the provisions of Table 1 or Table 2, respectively.

5.2. The effective value of the vibration speed of the motor shall not exceed 2.8mm/s.

6. Structure, installation, and overall dimensions

6.1. Motor structure and installation type

The structure and installation form of the YB2 series high-voltage three-phase asynchronous motor is IMB3, and its installation and external dimensions are shown in Table 3.

6.2. Structure of motor junction box

The motor junction box has excellent explosion-proof structural performance and high protection level, and has a large cavity for easy wiring. There are wiring bolts inside the junction box for reliable fixation of external lead cables. A rubber sealing device is installed at the wiring port. The diameter of the rubber sealing sleeve is φ 65 φ 58 φ 51 φ 44 φ 37 concentric circles are suitable for lead cables with different outer diameters. The end of the wiring port is equipped with a device to prevent cable detachment or a steel pipe wiring interface.

7. Iṣeduro didara

The company regards product quality as the life of the enterprise. We have successively obtained ISO9001, ISO10012, OHS18000, and ISO14001 management system certifications. The first explosion-proof motor to obtain a production license.

We have internationally advanced software and have achieved virtual prototype design and development. A complete product development system is composed of various links such as design engineering analysis simulation assembly failure mode analysis.

We have the most advanced process equipment and quality testing equipment in China. Process, manufacture, and inspect the first component according to the quality plan and quality control. Conduct final inspection and performance testing of the product.

According to the company's quality assurance statement, provide excellent services at every stage of product sales.

8. Ordering Guidelines

Please indicate the model, rated power, synchronous speed, rated voltage, rated frequency of the motor when ordering